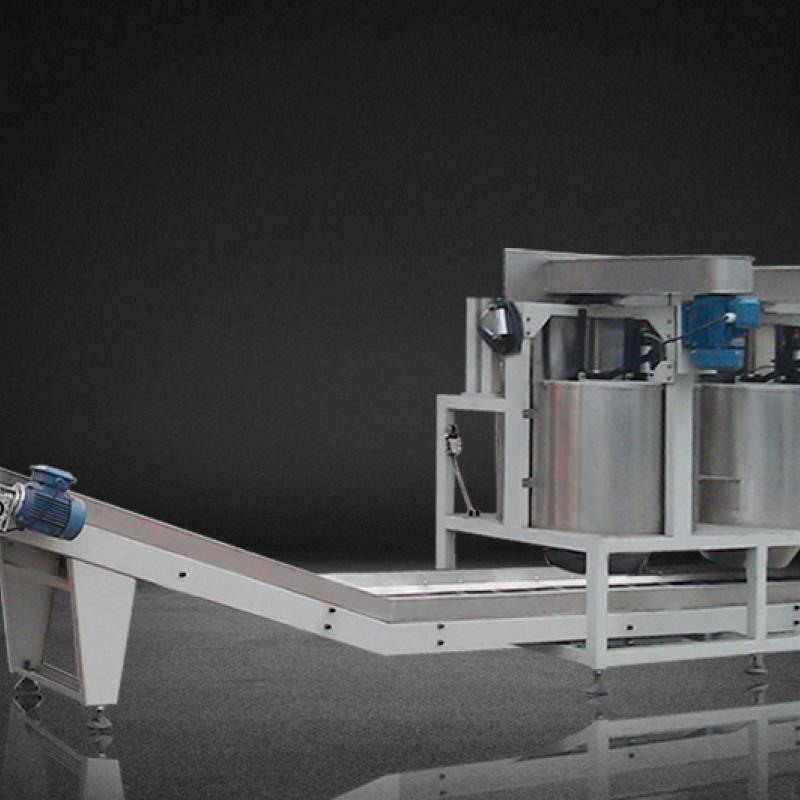

Snow flake and bread bran production lineThe snowflake and bread bran production line is exclusively developed and produced by Dayi, which is the first in China and another innovative application of twin-screw extrusion technology. The production process has been fully automated.

Связаться сейчас

The bread crumb production line developed by our company adopts a twin-screw extrusion puffing process, which converts flour or other powdered grain raw materials into crumbs, needle shaped or flake shaped bread crumbs and snowflake flakes. The production process includes feeding, mixing, puffing, cooling, crushing, etc. Compared to traditional baking methods for producing bread bran, the use of puffing technology has advantages such as high yield, high continuous production capacity, energy conservation, and labor saving.

Связаться сейчас

Overview:The equipment is reasonable in design, easy to operate, and low in price. It is also equipped with a chassis for placing the receiving box and discharging conveying.

Связаться сейчас

OverviewThis complete set of equipment is widely used, and can fry various foods such as potato chips, shrimp sticks, and rice noodles. This complete set of equipment integrates the functions of frying, oil rejection, and lifting. A series of actions are controlled by PLC centralized automatic control, which makes the control accurate and reliable, greatly improves the production efficiency, and saves a lot of human resources.

Связаться сейчас

This process line uses potato starch, corn starch as main materials to produce a variety of twice extrusion food in different shapes which are popular in the market, such as crispy pea, shell, screw, square tube, round tube, wave, etc. This process line is characterized by unique technics, rational configuration, high automation and stable performance. It can finish steaming, extruding and shaping in one step without a boiler.

Связаться сейчас

This process line uses potato starch, corn starch as main materials to produce a variety of twice extrusion food in different shapes which are popular in the market, such as crispy pea, shell, screw, square tube, round tube, wave, etc. This process line is characterized by unique technics, rational configuration, high automation and stable performance. It can finish steaming, extruding and shaping in one step without a boiler.

Связаться сейчас

This method line is newly designed and produced with foreign places advanced era. it has progressed the dangers of import device which encompass massive funding and excessive production rate. this line uses corn starch, wheat flour, potato starch as substances to supply"bugles", "internet", "potato chips" and loads of numerous three-d compound extrusion food. this line may be in assessment with those import equipments. under the same skills, its fee is superb one tenth of that of import device.

Связаться сейчас

Fish food making machine endues puppy meals with the quantity of nutrients, digestible shape, novel form, and unique taste to satisfy with the needs of modern-day marketplace. the dog chewing meals is extruded into an expansion of shapes including stick, bone, and many others.

Связаться сейчас

The artificial rice production line adopts the industry's advanced production and processing technology, and innovatively processes rice flour, wheat flour and nutritious, green and healthy grains that are not easy to process, taste bad, and digest into various artificial composite rice with the same cooking performance and cooking method as ordinary rice through the flexible way of single or multiple raw materials, adding or not adding nutrients. This artificial rice production line green, environmentally friendly, flexible, efficient, low failure rate, and small investment.

Связаться сейчас

Rice kernal making machine is one of the newly developed double-screw extruding techniques of our corporation. the conventional stir-fry handiwork has low efficient and much less usable uncooked substances, and its sanitation and fine are difficult to govern. the double-screw extruding method makes up the ones lacknesses. it now not handiest can method grain materials, like buckwheat, oats, etc.

Связаться сейчас

This process line is one of the newly developed double-screw extruding techniques of our company. The traditional stir-fry handiwork has low efficient and less usable raw materials, and its sanitation and quality are difficult to control. The double-screw extruding technique makes up those lacknesses. It not only can process grain materials, like buckwheat, oats, etc.

Связаться сейчас

Introduction of nutritional rice and instant rice production lineNutritional rice and instant rice production line is a food production equipment developed by Dayi according to the development trend of food in my country.There are two production processes of nutritional type and brewing type. The overall operation is stable, the degree of automation is high, and the operation is simple.

Связаться сейчас

This Puff Snack Making Machine Can Use Corn, Rice, And Other Grain Powder As Raw Materials To Produce Directly Puffed Snacks In Variou Shapes, Such As Chip, Ball, Ring, Stick, Flake, Flower, Etc. After Dried And Flavroed, The Snacks Are Crispy And Tasty Which Are Very Popular In The Market.

Связаться сейчас

Fish food process line endues pet food with the amount of nutrition, digestible structure, novel shape, and unique taste to meet with the needs of modern market. The dog chewing food is extruded into a variety of shapes such as stick, bone, etc.

Связаться сейчас

This process line adopts advanced share extrusion technology, which can extrude products with different textures and tastes out of double- screw extruder at the same time. It can produce a variety of core-filling food which are popular in the market, such as fragrant chicken, core- filling rolls, etc. It can also produce nutritional powder, grain gruel and many other snacks by changing moulds and assistant equipments.

Связаться сейчас

Nutrition powder and baby food production line is another new expansion application of Dayi in twin-screw extrusion technology. It has the characteristics of high degree of automation, strong stability, simple operation, high output, short process time, etc., and effectively improves various drawbacks in the original tradition, and the processing raw materials are also more extensive. At the same time, various nutrients can also be added according to customer process requirements to produce multi-functional nutritional and health food

Связаться сейчас

The nutritional powder production line developed by our company is a new extension and application of twin-screw extrusion technology. The traditional manual frying method for nutritional powder has low efficiency, hygiene, and quality issues that are difficult to control, resulting in a single processing material. Twin screw extrusion technology makes up for the above shortcomings. It can process a wide range of raw materials, including Rice noodles, corn flour, soybean flour, buckwheat, oats, etc. This production line can also add various nutrients such as vitamins, proteins, etc.

Связаться сейчас

The core filling snacks production line equipment developed by our company is completed in one go from raw material preparation, to extrusion and puffing, sandwich, molding, cutting, spraying, seasoning, and finally to finished products, with a high degree of automation. This production line has the characteristics of multiple configuration models, flexible configuration, wide range of raw materials, multiple product types, and simple operation.

Связаться сейчас

The fully automatic nutritional rice production line is developed to address the significant loss of nutrients in rice during traditional rice milling production processes. Rice and other nutrients can be made into high value-added products through extrusion technology. During this process, broken rice and rice bran can be reused. The entire production process is simple and easy to operate. After crushing the broken rice, it is mixed with a certain amount of water, oil, etc.

Связаться сейчас

The nutritional rice production line uses Rice noodles as the main raw material, which can be selectively filled with various vitamins and minerals as required. The shape of the rice grains is extruded by the twin-screw extruder, and then dried to the required moisture. It can be eaten after cooking for about 10 minutes. The nutritional rice artificial rice production line endows rice with unique shapes, flavors, and colors, and adapts to the constantly developing market for health and wellness foods with scientific nutritional ratios and easy digestion.

Связаться сейчас

The nutritional rice production line developed by our company takes Rice noodles as the main raw material, and can selectively fill a variety of vitamins and minerals, such as vitamin B, vitamin C, vitamin A, etc. according to production needs. Extrude the shape of rice grains through a twin screw extruder, then dry to the required moisture content, and cook for 5-10 minutes before consumption. The extrusion puffed rice production technology developed by our company makes it possible to strengthen trace elements in rice.

Связаться сейчас

Nutrition powder and baby food production line is another new expansion application of Dayi in twin-screw extrusion technology. It has the characteristics of high degree of automation, strong stability, simple operation, high output, short process time, etc., and effectively improves various drawbacks in the original tradition, and the processing raw materials are also more extensive. At the same time, various nutrients can also be added according to customer process requirements to produce multi-functional nutritional and health food.

Связаться сейчас

Equipment introductionThis machine is a special equipment for drying semi-puffed food. It can dry food blanks of various shapes such as potato chips, French fries, spirals, shells and crisp corners. It has a wide range of applications.This machine uses the combustion chamber for heating, and uses the chain to drag the stainless steel mesh belt for transmission. And it is equipped with an advanced frequency conversion speed regulation system, which can set different transmission speeds according to different materials.

Связаться сейчас

This Puff Snack Making Machine Can Use Corn, Rice, And Other Grain Powder As Raw Materials To Produce Directly Puffed Snacks In Variou Shapes, Such As Chip, Ball, Ring, Stick, Flake, Flower, Etc. After Dried And Flavroed, The Snacks Are Crispy And Tasty Which Are Very Popular In The Market.

Связаться сейчас